Our daily scenery: A video tour of our daily operations

August 2020

We have released a video of the inside of our factory.

Please feel free to watch if you like.

April, 2020

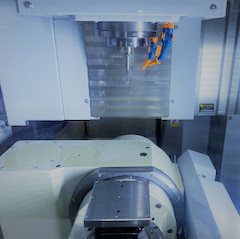

Announcement: Introduction of a new processing machine

March, 2020

We have introduced a small-size precision processing machine μV1 from MITSUBISIHI.

This machine is equipped with some MITSUBISHI’s independently-developed functions, including an optical image type tool measuring system.

It has a highly technical advantage such as minimum errors in processing step boundaries of the processed surface; so we intend to use it for processing precision molds and high-precision parts in the realms of IT, optics, medical equipment, semiconductor devices, and so on.

We will keep on developing products, improving quality and providing services to satisfy our customers.

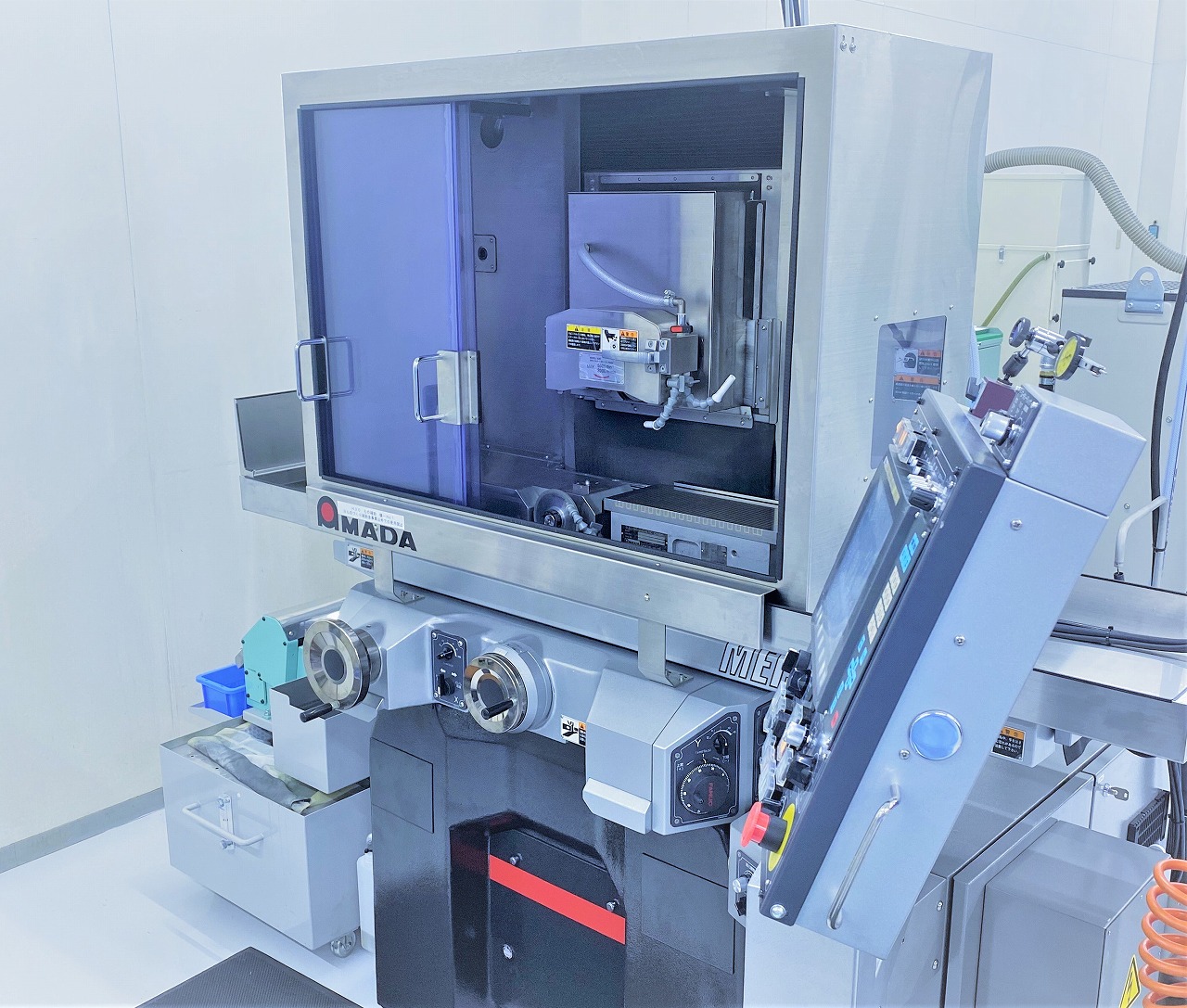

Announcement: Introduction of a new processing machine

March, 2020

We have introduced an additional MEISTER-V3 from Amada Machine Tool.

Specifications of MEISTER-V3

Standard chuck size

(Length x width x height) (mm) 350 x 150 x 100

Travel distance

(front/rear, left/ right, up/ down) (mm) 200/500/400

Grinding wheel size

(Outer diameter x width x inner diameter) (mm) φ205 x 15 x φ31.75

Although we had already owned and operated MEISTER V3, the additional introduction enabled us to add various products with special equipment, including single rotary dresser devices.

Highly efficient dressing is now possible with a rotary dresser of Max 3000 min-1 which potentially leads to a further improvement in machining accuracy of shape processing as well as a further reduction of preparation time by automating the grinding stone forming and dressing work.

We will keep on developing products, improving quality and providing services to satisfy our customers.