September, 2017 GX350 Amada 1 unit

Processes workpieces up to φ 350 mm × height 250 mm

A processing machine that combines 5-axis milling, turn-milling, and grinding. It is larger processing machine than the formerly introduced MX150.

September, 2017 MEISTER V3 (Amada) 1 unit

Maximum chuck size X×Y×Z (mm): 350×150×100

Travel distance X×Y×Z (mm): 500/200/400

February, 2015 MX150 (Amada) 1 unit

NOVEMBER, 2016 MX150 (Amada) 1 unit

Travel distance X×Y×Z (mm): 350x300x400 mm

Processes workpieces up to φ 350×250 Max. Workpiece Mass (kg): 10

Max. Spindle Speed (min-1): 42000

A processing machine that combines 5-axis milling, turn-milling, and grinding.

We were able to successfully manufacture a product with position-accuracy tolerance of ±0.5µ that met our client's high expectations for quality.

February, 2017 AP1L (Sodick) 1 unit

Ultra-precision die-sinking EDM

Travel distance X×Y×Z (mm): 200×120×200

Screw-less driving and highly rigid structure

February, 2017 TF-H1 (Amada) 1 unit

Maximum chuck size X×Y×Z (mm): 450×150×70

High-speed reciprocating grinding machine. It is used to fulfill higher precision and to shorten lead-times in the form grinding process.

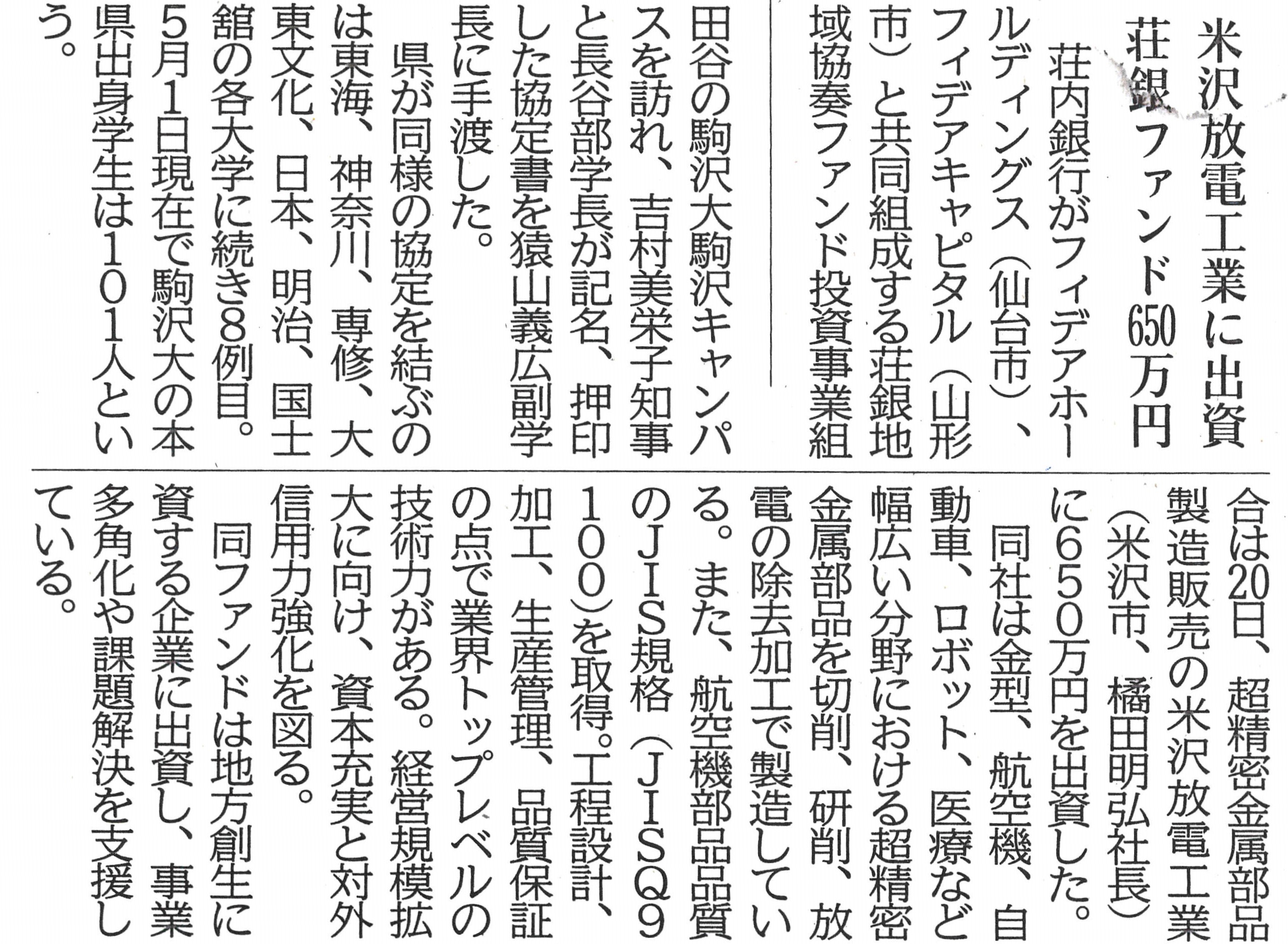

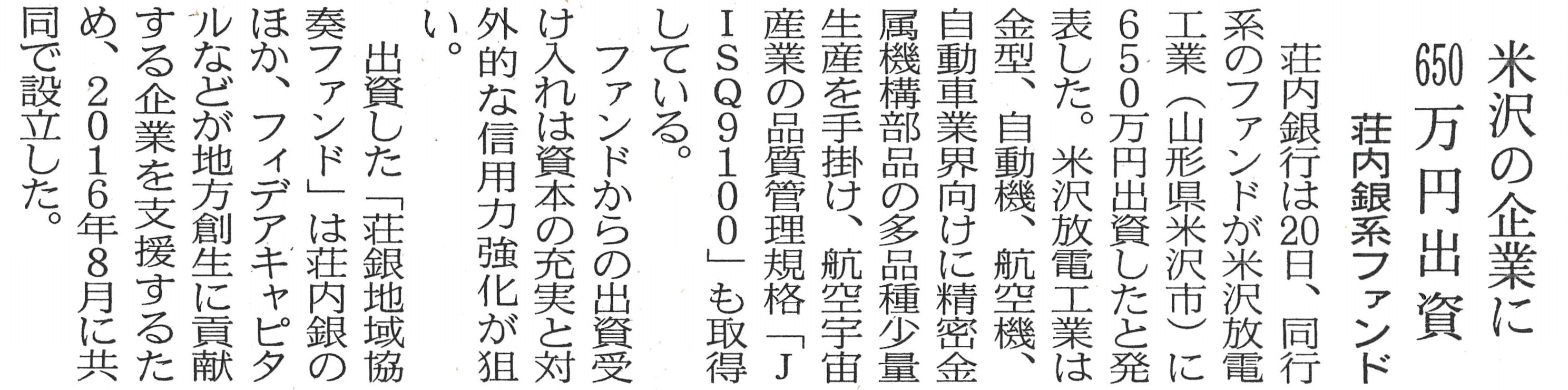

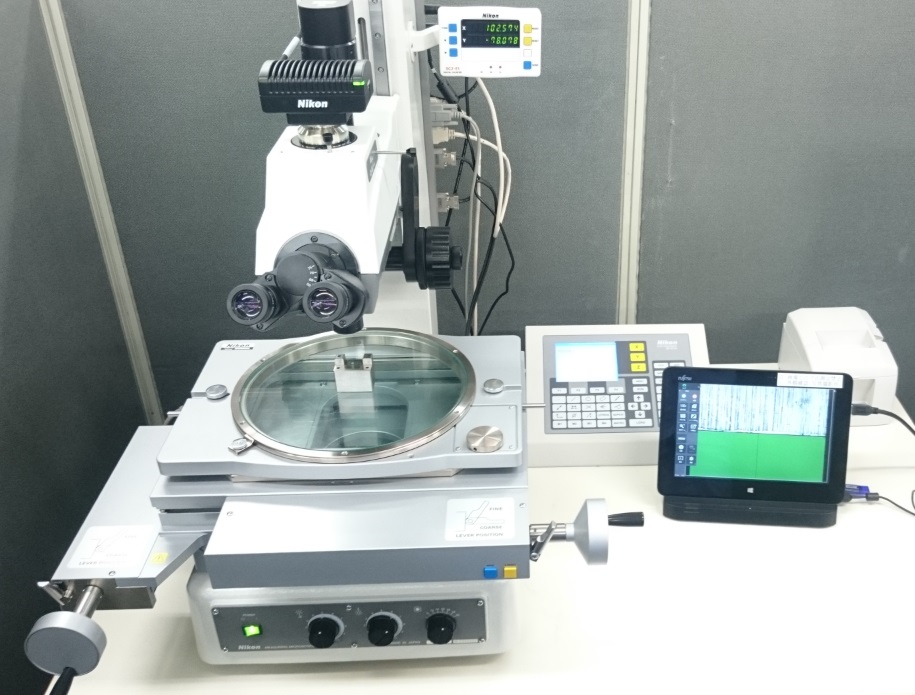

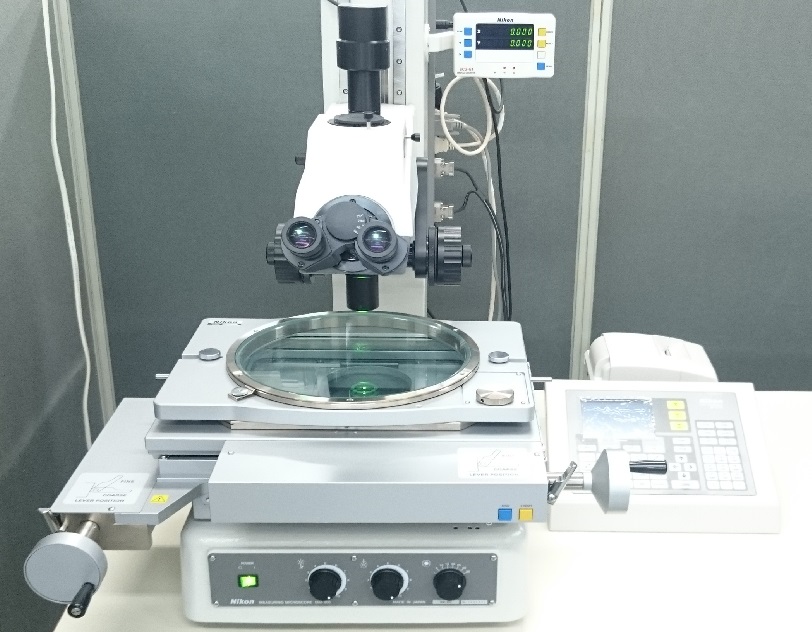

April, 2017 MM-800/T(NIKON) 2 units

Dimensions/weight: 380(W) ×735(D) ×725(H) mm, approx. 72kg

These make it possible for us to improve the precision of products in measuring each workpiece between manufacturing processes as well as to measure both R and taper and to observe processing conditions with a 100x magnifying camera.

May, 2017 MB-46VA(Okuma) 1 unit

Travel distance X×Y×Z (mm): 560/460/460

Spindle speed: 15,000rpm

Guaranteed accuracy of ±0.003

August, 2017 MV2400R (Mitsubishi Electric) 1 unit.

Wire-cut EDM (Electric Discharge Machine) using water as a machining fluid.

Travel distance X×Y×Z (mm): 600/400/310

We can handle big-size and/or high-precision processing.

August, 2017 AP250L (Sodick) 1 unit

Travel distance X×Y×Z (mm): 250/150/120

Wire-cut EDM (Electric Discharge Machine) using oil as a machining fluid

We handle requests for high precision processing and high surface roughness.

August, 2017 SH12M (Mitsubishi Electric) 1 unit

Fine-hole processing machine using water as a machining fluid.

Travel distance X×Y×Z (mm): 400/300/380

This is the second unit. This one is without a robot.

Processing available for a range from the minimum size of Φ0.1 up to the maximum size ofΦ3.5

We are capable of responding to your requests for holes of small diameters within a shorter lead-time.