December, 2015

We wish to inform our customers that we will be closed during the year-end and New Year holidays, and will not be available to respond to requests and queries during this time. We apologize for any inconvenience this may cause you.

Year End Holiday Dates: 30th December - 4th January

“Yamagata Monozukuri (manufacturing) Prefecture”,an article appeared in Yamagata Newspaper

November, 2015

Appeared in Yamagata Newspaper, November 22nd

Members of the Hitachi Iron and Steel Association visited for a company tour

November, 2015

Members of the Hitachi Iron and Steel Association visited for a company tour. We were grateful to show them how our operational procedures were conducted.

The 5th RIT Business Presentation Seminar

October, 2015

As part of Regional Industry Tie-up (RIT) Program, we welcomed visitors from Saxony, Germany for a company tour.

NS Business Management Seminar

September, 2015

Sponsored by NS-Tool, a seminar was held at our company hosting approximately 30 participants from various companies related to the fabrication of 5-axis precision composite parts. Presentations on the latest technology were given which brought about valuable experience to every participant. The seminar was co-sponsored by Kodama Corporation, Ltd., Ricoh Industry Company, Ltd. and Plant Yonezawa, Inc., and organized by NC Network Office. We wish to thank all participants for making it a success.

High school students’ plant visits

June 26th, 2015

Third-year students of Yonezawa Chuo High School visited for a company tour.

The company tour was performed to provide career guidance so that they could increase awareness and knowledge of real-world jobs.

May 26th, 2015

Third-year students of Kunori High School visited our company as part of their career guidance.

We sincerely hope their visit to our company could be useful for their career options.

Introduced a multifunction processing machine, which allows us to create completely new processing technologies.

March, 2015

Amada Machine Tools MX150

Achieving both high efficiency and accuracy, Multi Process Center combines 5-axis milling, turn milling, and grinding functions in a single unit. By fully utilizing it, we aim to keep providing higher precision processing and superior surface finish.

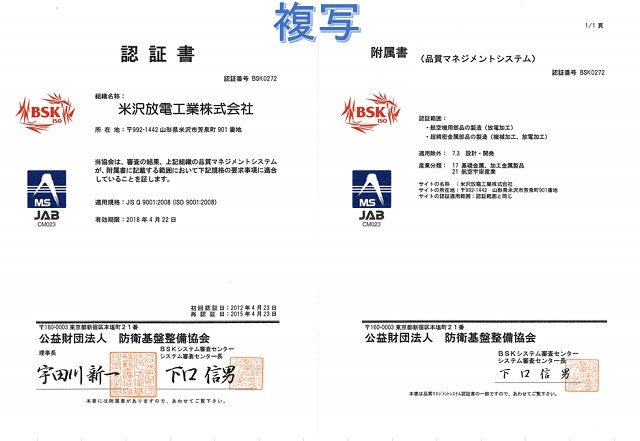

Acquired JIS Q9100 (Aerospace Quality Management System)

April, 2015

On April 23rd, we regained JIS Q9100: 2009 and JIS Q9001: 2008 (ISO 9001: 2008)Aerospace Quality Management System certification issued by the Defense Structure Improvement Foundation (BSK System Assessment Center).

The system positively affects the performance of our core business, the manufacture of high-precision mold/die parts and high-precision automated machine parts, as well as the manufacture of parts used for jet engines and in the aerospace industry.

We aim to keep providing safe, environmentally friendly, ethical, high quality, timely, and cost-effective service, continuing to grow as a socially responsible company.